Robotic production benches

We eliminate the human factor from onerous or dangerous processes

- sequence and component orientation control

- reduction of assembly time

- ensuring assembly repeatability

- elimination of direct operator participation

- tracking components used for assembly and recording process parameters (traceability)

- one lines ensuring the possibility of mounting many variants

- solutions fitted to the customer's production volume (MSD)

Collaborative Robots

We automate production with Cobots (Collaborative Robots).

We can implement a robot, which will be able to work with an operator (or work independently) on repetitive processes. This solution has great flexibility, because programming the robot is very simple and allows to quickly change its workplace.

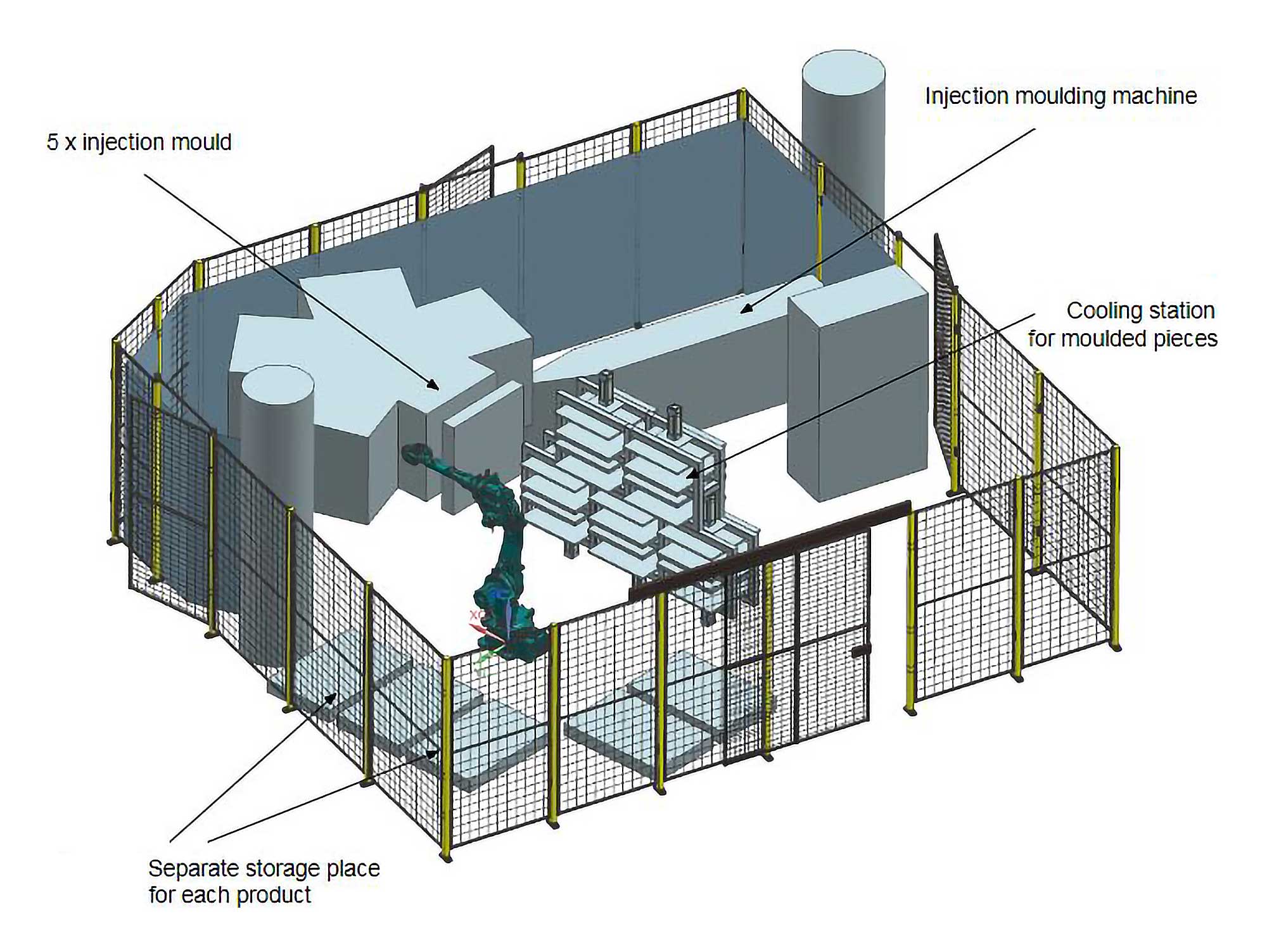

CUSTOMER

TecSolum

CASE STUDY

brushing head base for vehicles maintaining runway cleanliness

ISSUE

The customer needed a robotic pickup directly from the carousel injection molding machine.

The reception of components by the operator were very onerous due to its high temperature. Hot plastic parts also could not be dropped into containers due to the risk of deformation. In addition, it was necessary to ensure even temperature reception on a flat surface after putting away the element.

The limitation was a tact of 15 seconds - taking and putting the component from the machine to the storage place.