instruments for quality control

"

- the ability to measure critical or key characteristics

- we provide gauges with high tolerance: 0.02mm

- recording of features measured in the report form (traceability)

- our experience in the automotive industry allows us to correctly orientate the detail in the global coordinate system of the vehicle and mapping the immediate surroundings of the detail

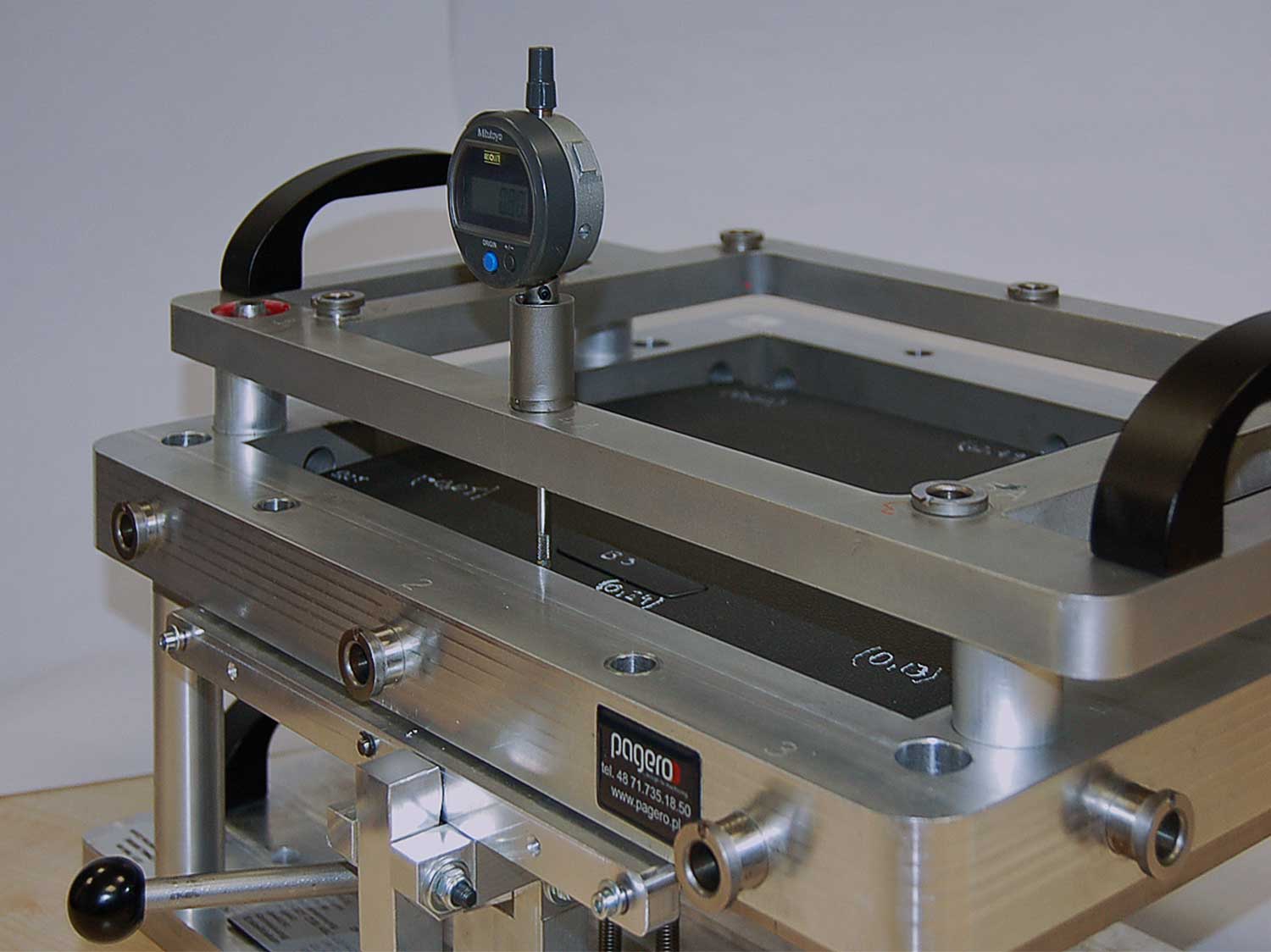

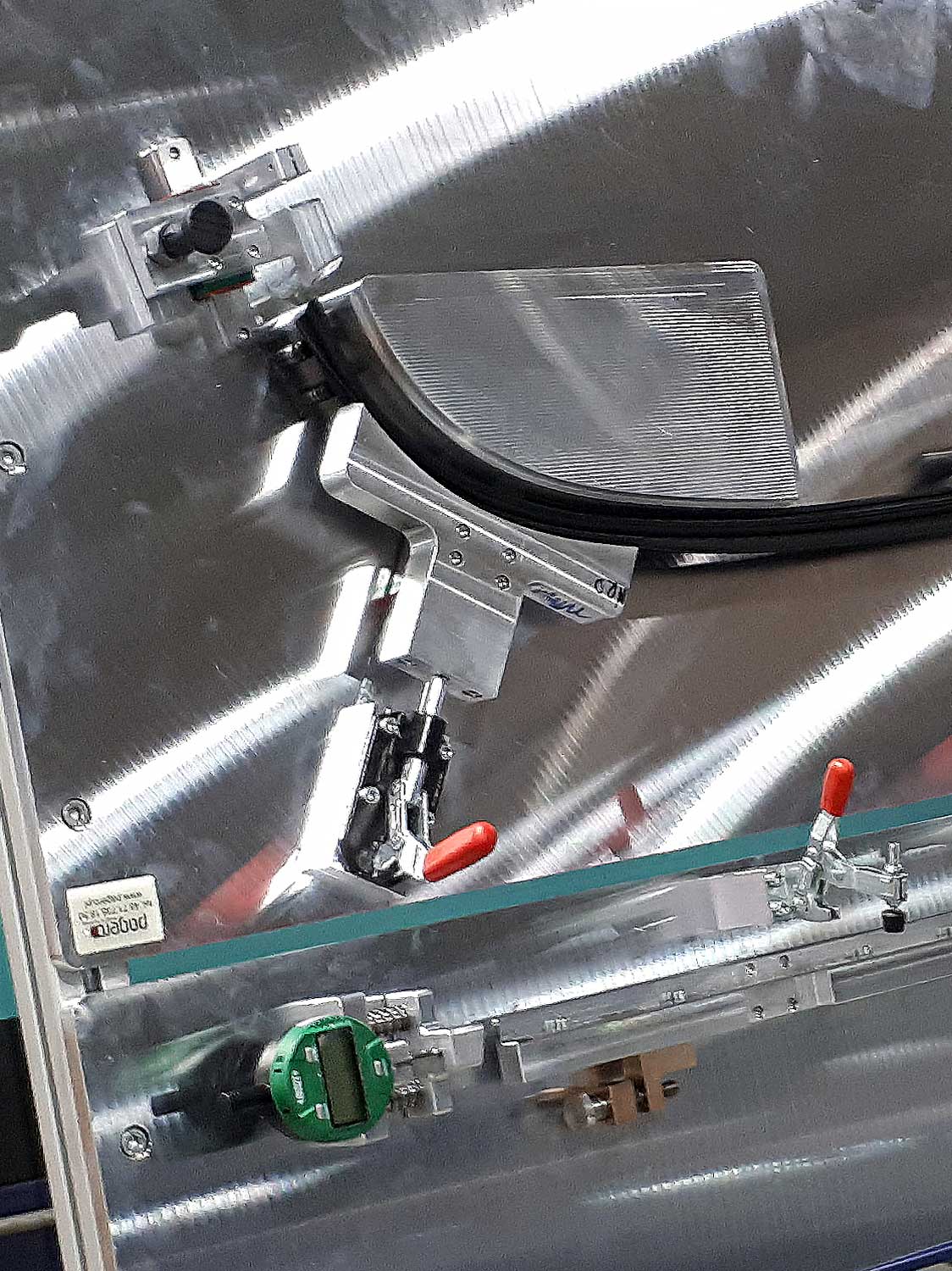

The customer needed a device for quality control, correct assembly of plastic elements and their compliance with the CAD design geometry.

Required accuracy for the whole instrument is 0.02mm.

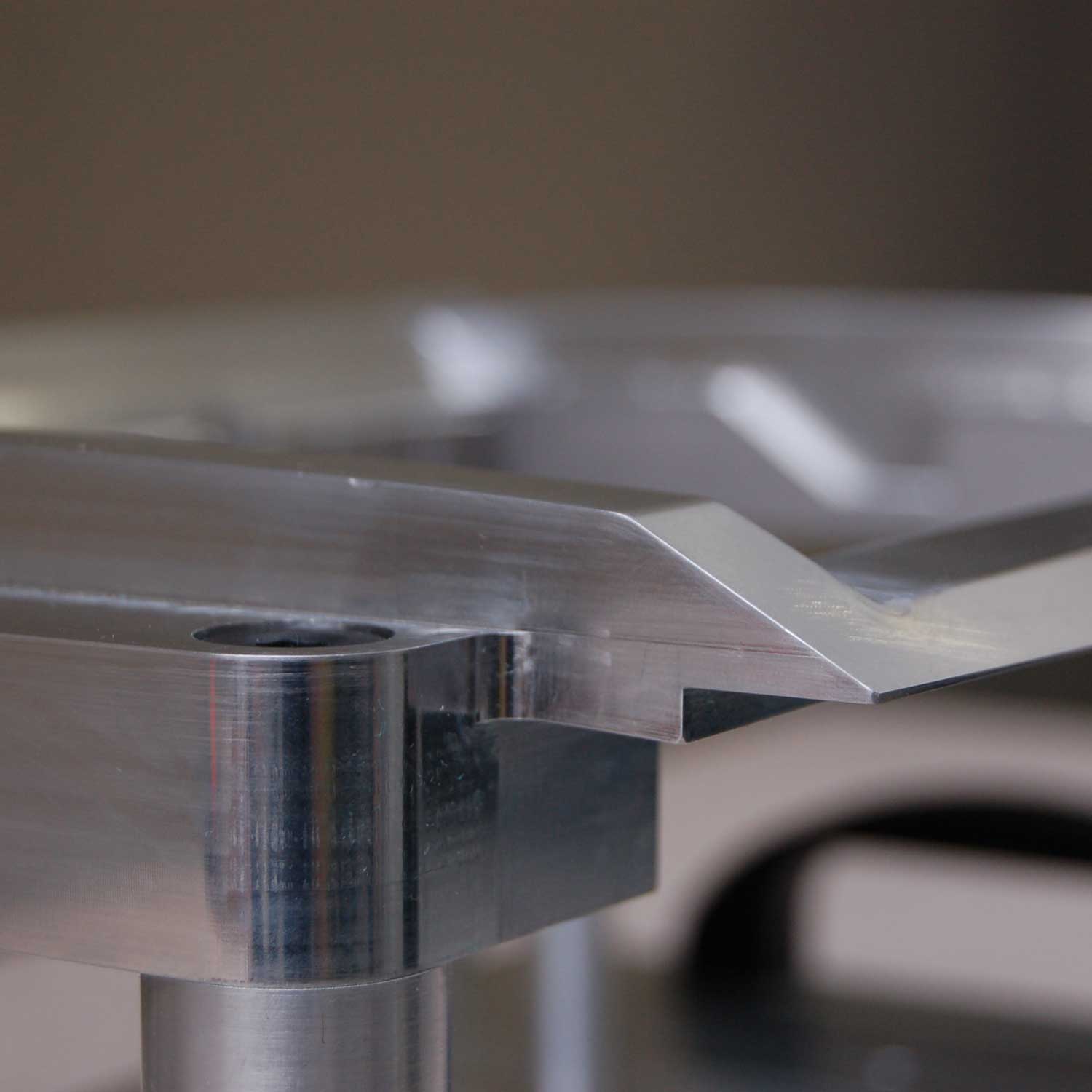

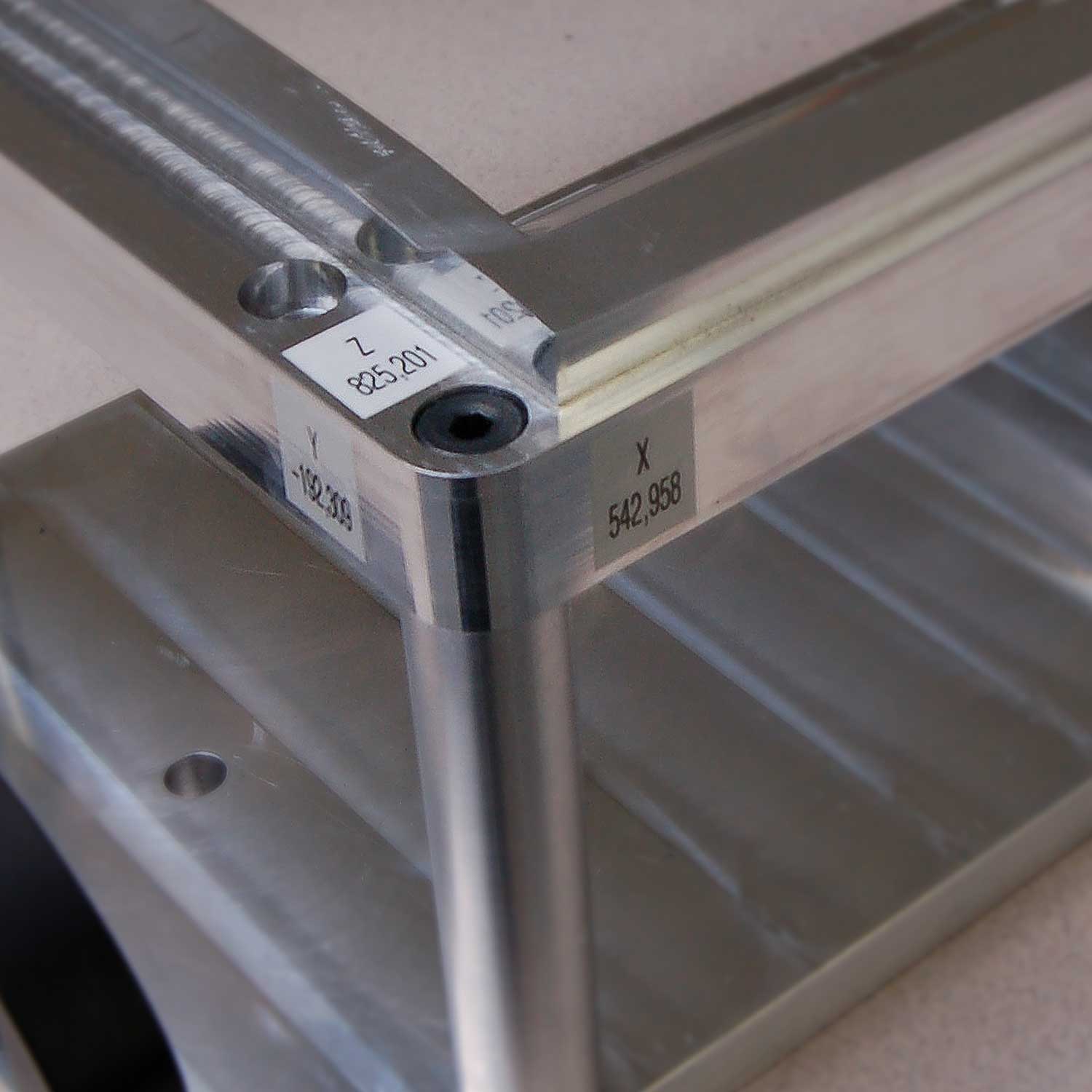

We designed and made a socket that reflects the geometry of the storage compartment environment (passenger car dashboard). The socket allowed for unambiguous manual assembly of the box - checking the condition of the correct assembly of individual product elements. In addition, our tool is equipped with dial indicators that allow you to control the geometry and points of RPS and MP according to the customer's drawing.

- Maintaining the mentioned accuracy required the implementation of POKA-YOKE on the dial gauge spindle - because dial gauge solutions available on the market allow it to rotate freely - which affected the accuracy of measurements.

- In order to maintain repeatable accuracy of measurements, our tool has been equipped with a precisely made calibration socket.

- The accuracy of the device was confirmed by the CMM measurement report.

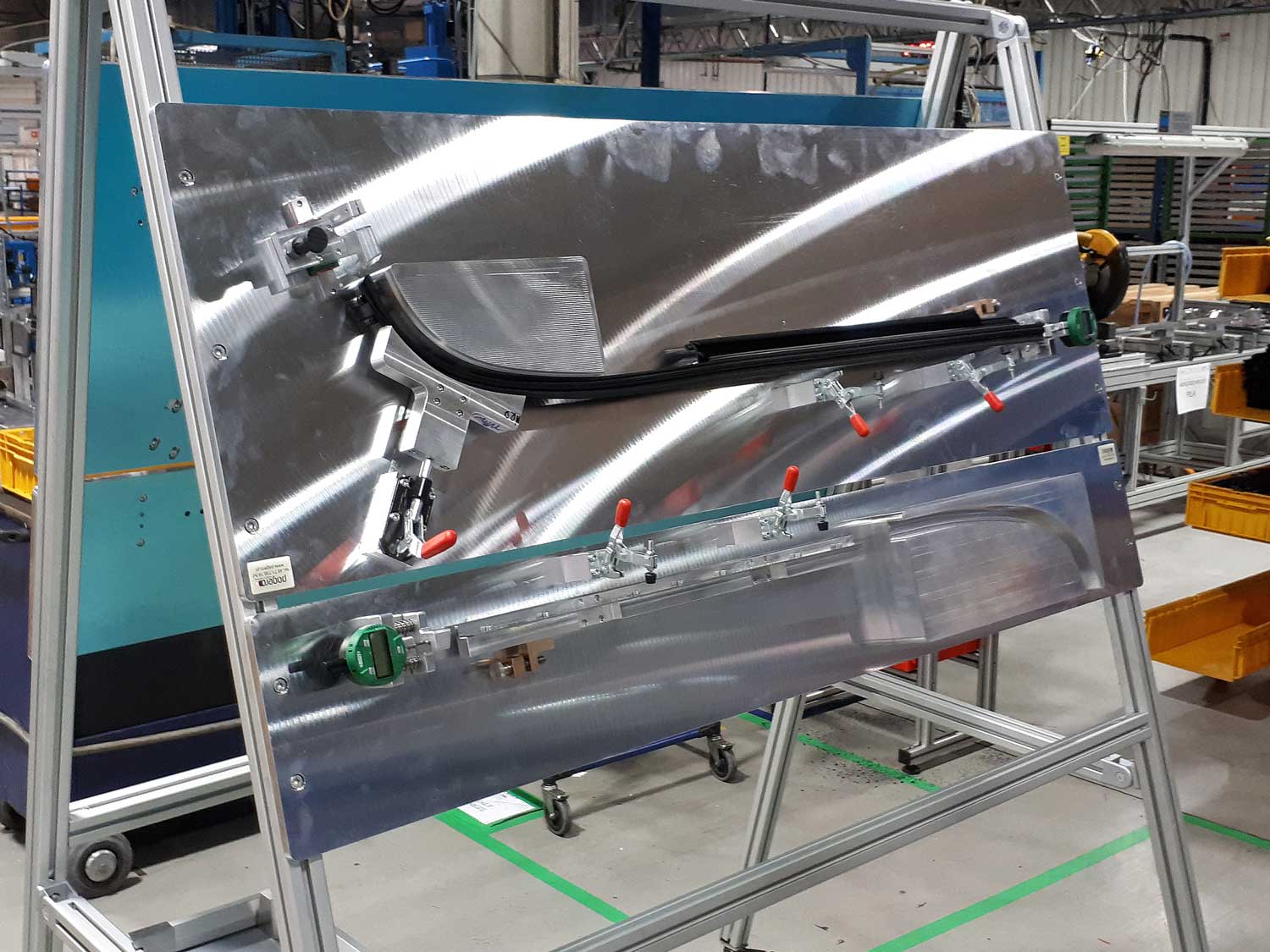

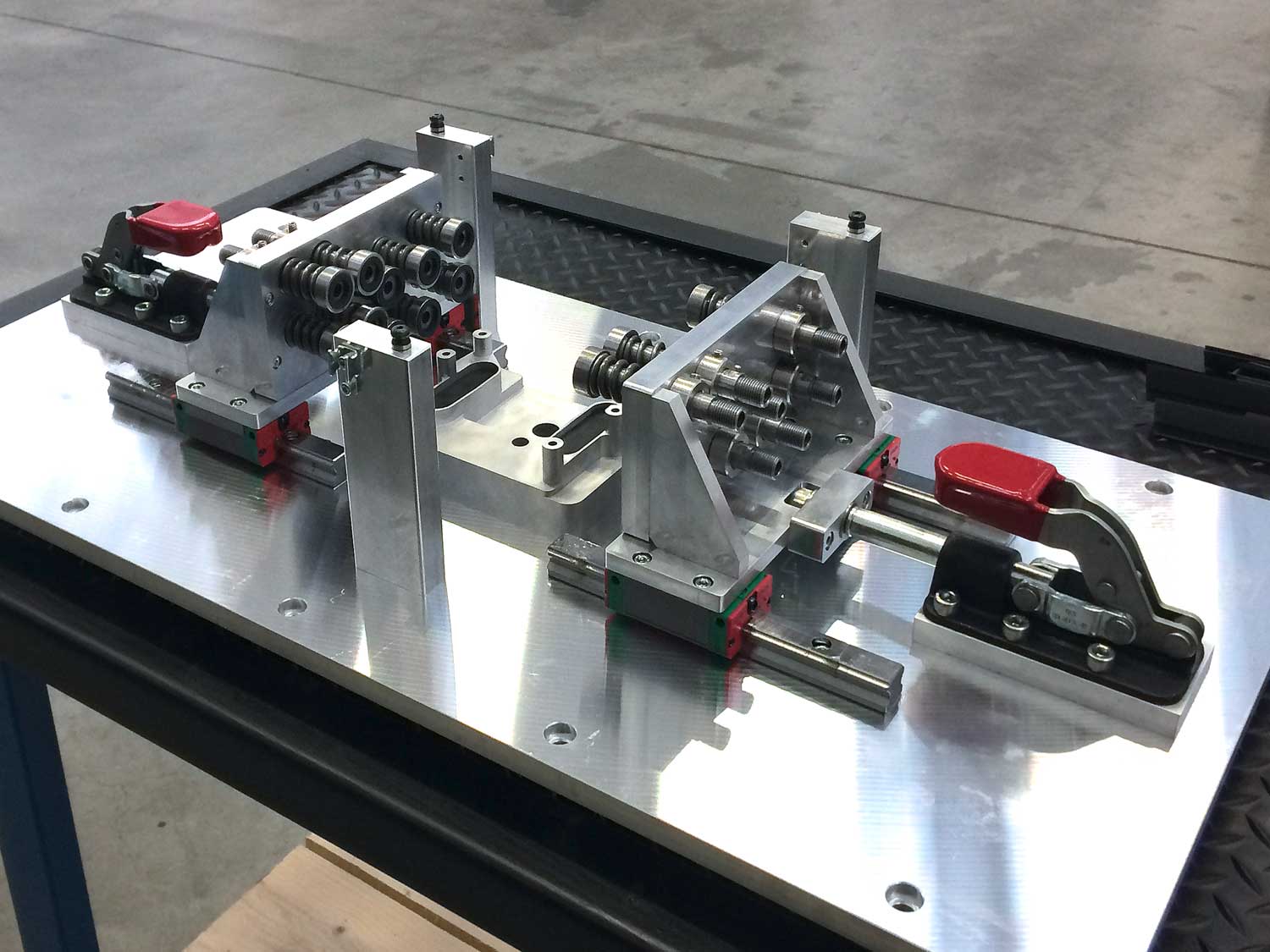

The client needed equipment to control the quality and geometry of car body seals.

Main challenges:

- dimensions about 1m

- the shape of the seals resulting from the body geometry

- low stiffness, susceptible to buckling"

- required precision

We designed and made sets of manual instruments that allow the control of geometry (bending shape and correct cutting angles), length.

The design of the device allows for easy use, while designing our goal was to make the operator's effort as low as possible - every produced seal is controlled.

The complexity of the seals required us to take into account the entire environment of the examined detail so that the elements of the sealing support in the device allow to eliminate the risk of deformation, which is why the instruments repeatedly reflect the shape of the car body (doors, side pillars and even windows) throughout their construction

Each control device has been equipped by PAGEO with a calibration element made of wear-resistant materials. The calibration elements reflect the 3D model with +/- 0.1mm accuracy.

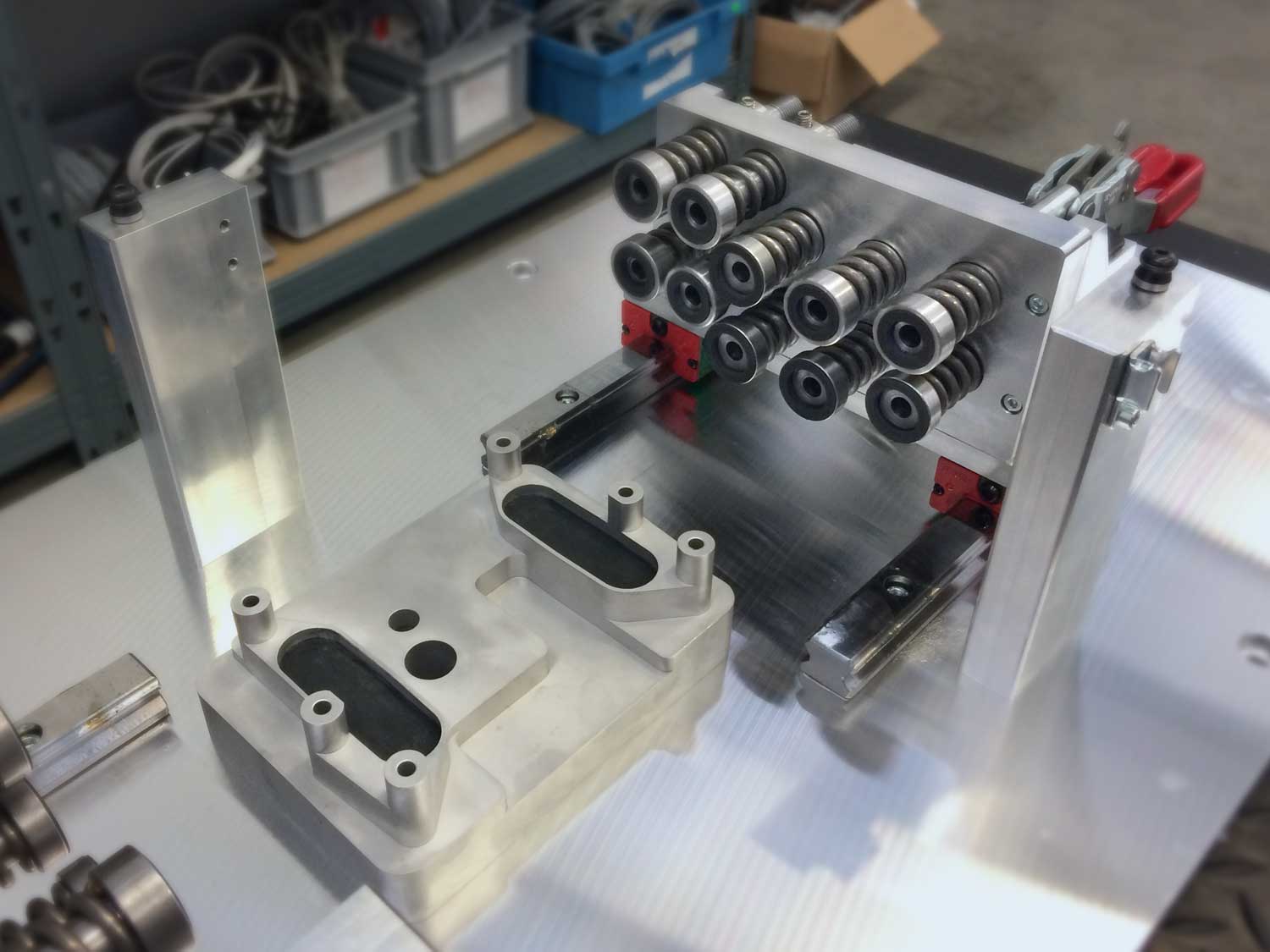

The customer needed to speed up manual assembly and leakage testing of prototype valves.

Designed and made assembly sockets have significantly accelerated the assembly process while maintaining adequate quality. We made two manual sockets that allow testing the tightness of prototype valves responsible for pressure modulation in the EBS systems of semi-trailers.

Particular attention should be paid to the heads created by us, consisting of carefully selected seals and a set of springs ensuring adequate clamping force, this solution has eliminated the risk of leaks on the interface of the device.

Thanks to the construction of special heads, we were also able to secure several pneumatic ports of different heights with one DESTACO clamp - which significantly reduced the time needed to examine the valve.